IBAA and the Circular Economy

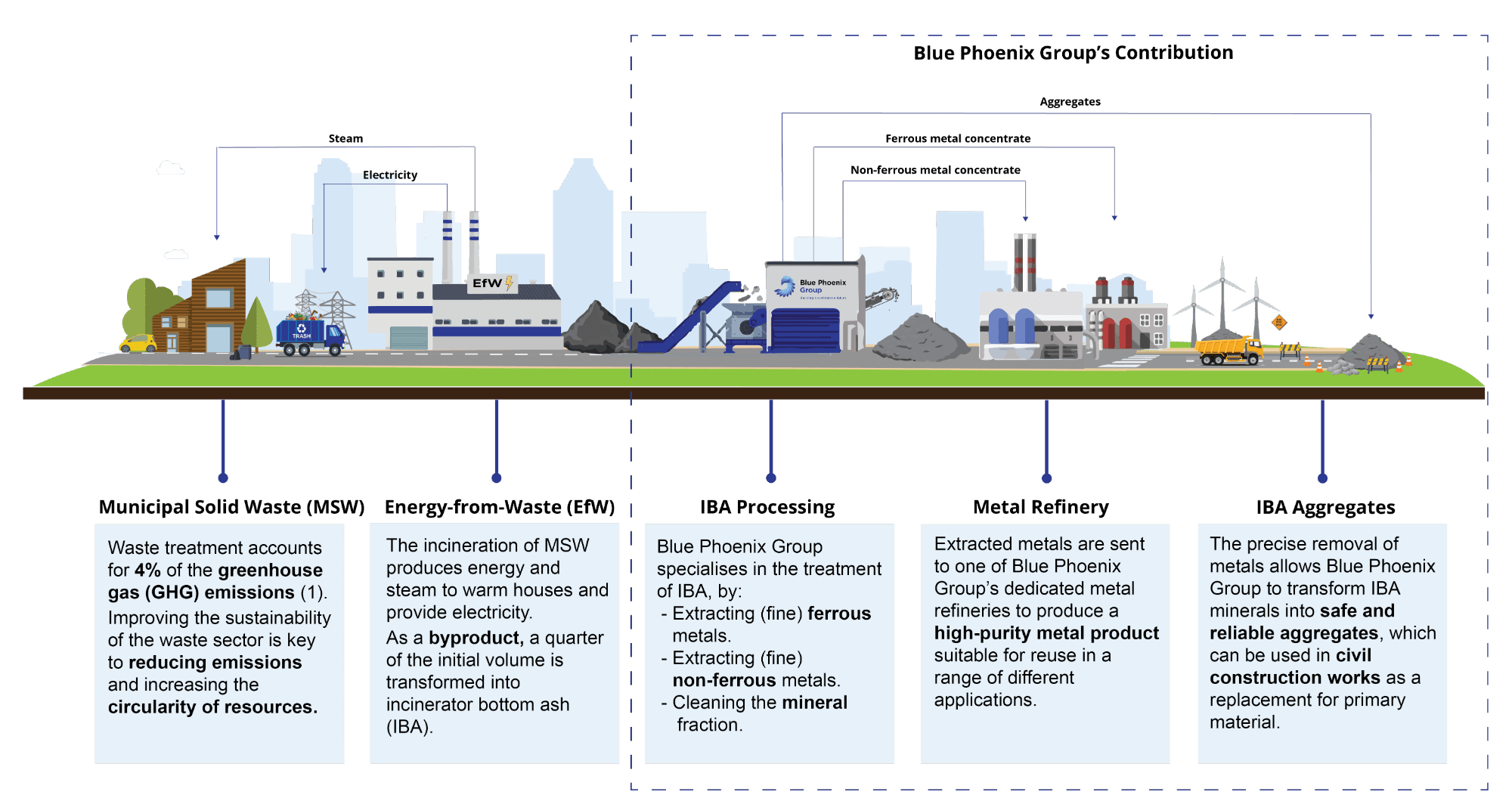

Every year, millions of tonnes of municipal solid waste (MSW) are generated, with a large percentage being disposed of in landfills. Energy-from-Waste (EfW) offers an alternative and allows for the recycling of non-recyclable waste. Through the EfW process, approximately a quarter of the initial mass of MSW is transformed into incinerator bottom ash (IBA). These EfW’s try hard to make the most from waste, nevertheless ash remains as the last residue. When residue ash is not recycled it is usually buried at a landfill site. As we keep producing waste, more and more of these sites are needed. An untenable situation in the long run. In parallel, the extraction of primary aggregates for construction and transport to construction sites places enormous pressure on the environment. Our mission is founded on finding a better, more sustainable way. At Blue Phoenix, we identified an opportunity here to give this ash a new life and close the recycling loop for EfW’s.

Giving ash a new life

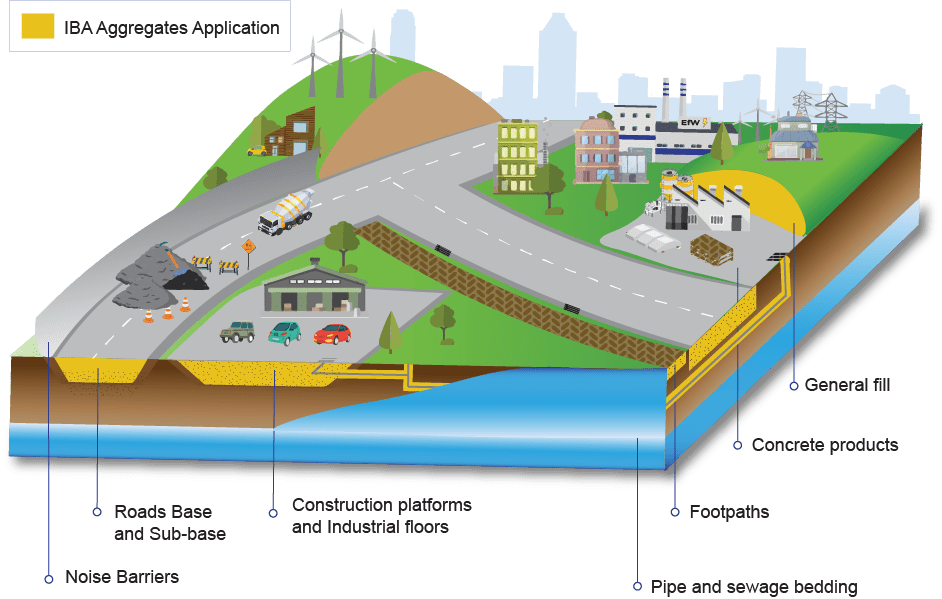

The vast majority of the incinerator bottom ash (IBA) consists of inert brick, rubble, glass, ceramics, and stone. With over 20 years of experience processing and handling IBA aggregates (IBAA), we believe that IBAA deposits can be better used and offer an alternative manufactured aggregate suitable for many applications.

The Circular Economy is central to the sector’s ambitions and Blue Phoenix is proud to be delivering excellence in secondary materials. Processing IBA, recovering metals and producing a resource from the remaining material that can be re-purposed into a usable aggregate can be an important factor towards meeting your ESG expectations and sustainability goals.

Innovative Operations

Blue Phoenix has an in-house Engineering, Procurement and Construction department, in addition to an expert engineering team, who are exploring new technologies and processes to enhance our offer to the Energy-from-Waste (EFW) industry with an ambitious sustainability programme working towards Net-Zero. It is our mission to reduce the dependency on mining and the depletion of the earth's resources while contributing to decreasing the carbon footprint of the civil construction industry.

The extraction of primary aggregates for construction and transport to construction sites places enormous pressure on the environment. The use of manufactured aggregates from IBA prevents landfilling, mining of virgin raw materials and contributes to the circular economy. The processing of IBA prevents valuable resources from going to landfill and produces manufactured aggregates that can be used in the same local area where the waste is produced is a rewarding solution that appeals to local authorities as purchasers of IBAA and suppliers of feedstocks to EfWs.

Adopting a circular economy has the power to significantly shrink global GHG emissions and cut virgin resource use. IBA processing contributes to this strategy by recovering, thereby diverting waste from landfills and reducing primary resource extraction. This in turn helps to improve the sustainability of the EfW sector.